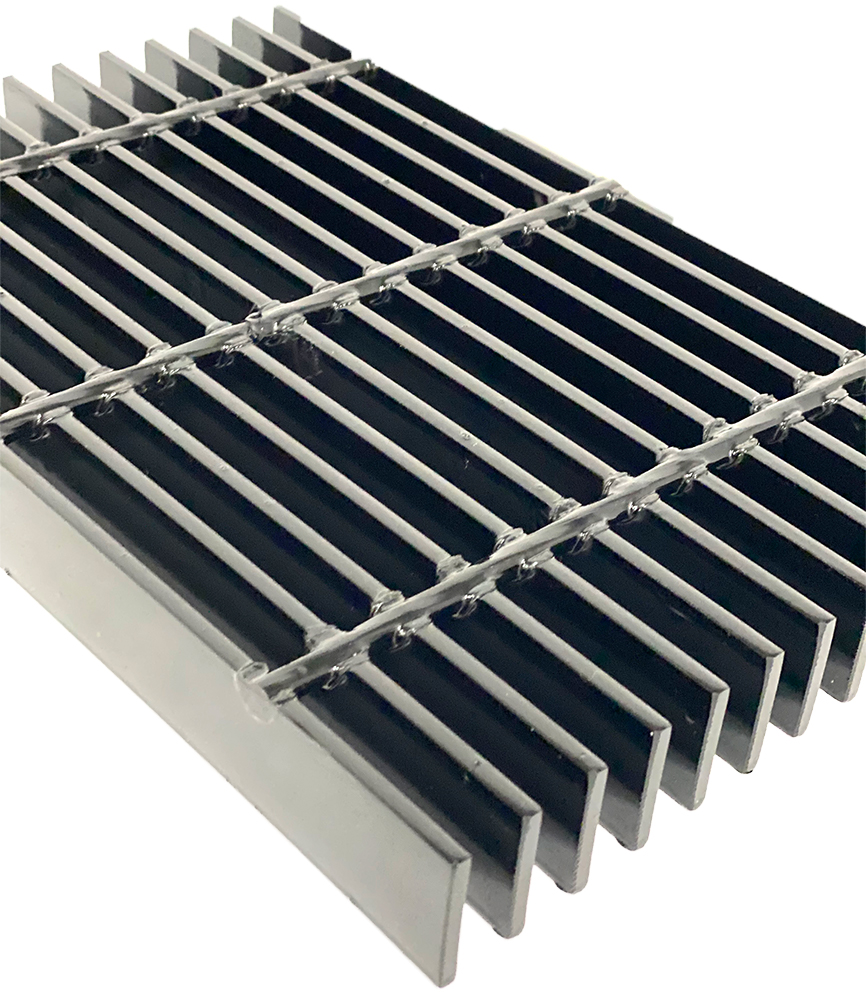

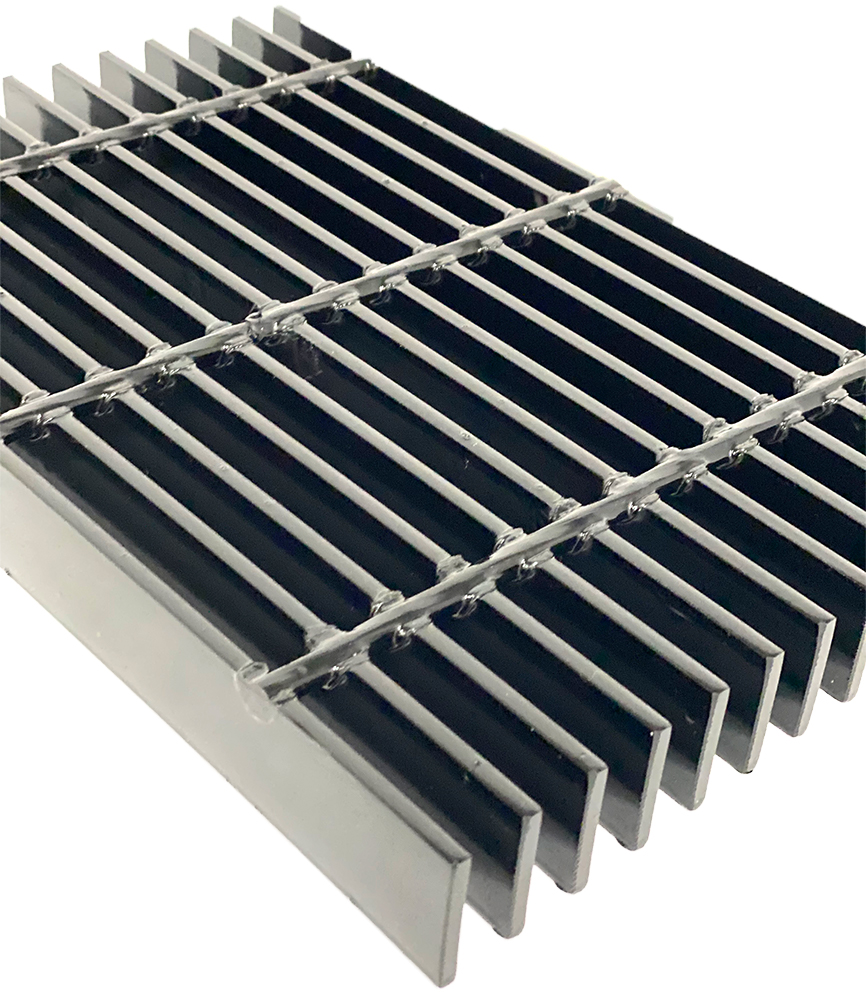

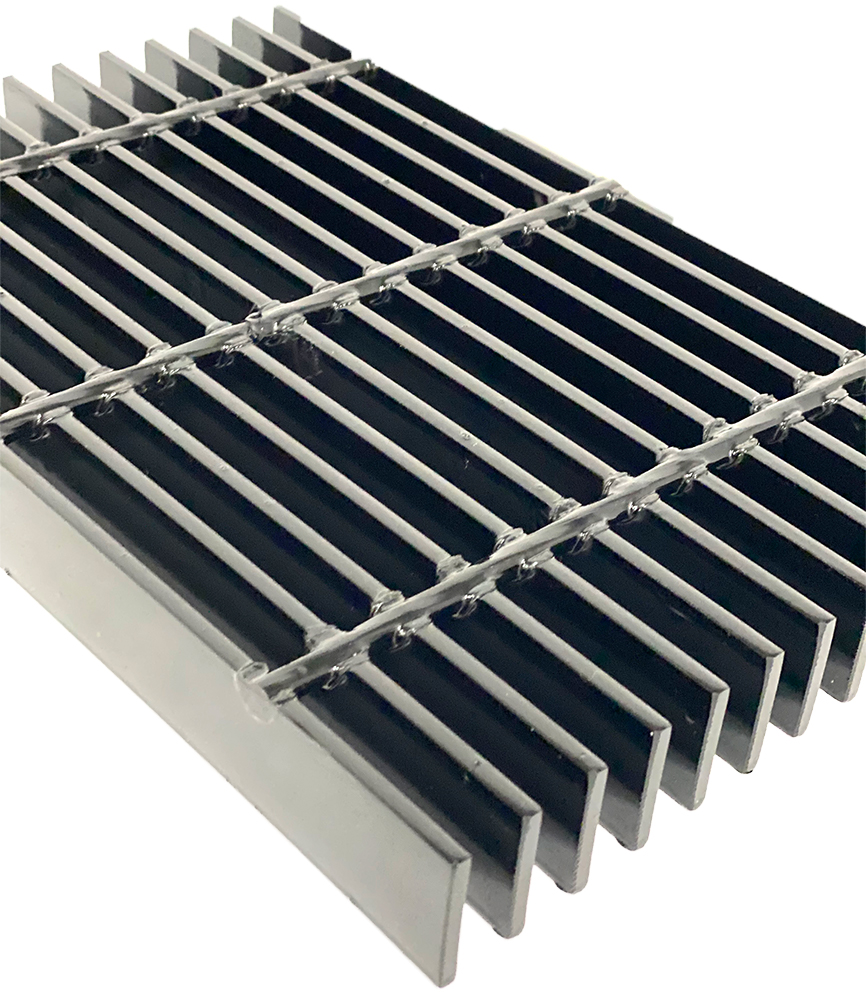

Metal Bar Grating is the workhorse of the industrial flooring market and has served industry for decades. Strong and durable with an exceptional strength-to-weight ratio, metal bar grating can be easily fabricated to nearly any configuration. The high percentage of open area makes bar grating nearly maintenance free and all products are fully recyclable.

Manufactured by assembling a series of equally spaced metal bars to connecting cross members, bar grating is available in three popular materials; mild carbon steel, 6000 series aluminum and 300 series stainless steels. Additionally, Interstate Gratings can produce gratings constructed with other specialty metal alloys. Get in touch with us to discuss your situation.

Economical design ideal for most industrial applications. Manufactured by welding the bearing bar/cross bar intersection, typically with automated forge welding equipment. Available in carbon steel and stainless steel.

Assembled by inserting pre-punched bearing and cross bars into an interlocking configuration and deforming the cross bars under intense hydraulic pressure. Available in all materials and ideal for many architectural and ornamental applications.

Popular for the manufacture of aluminum, stainless steel and close mesh gratings. Cross bars are inserted into pre-punched holes in the bearing bars and then hydraulically deformed to lock the bars in place.

Exceptionally durable grating manufactured by riveting bearing bars and bent connecting bars at their contact points. Excellent for applications involving impact loads and repetitive traffic patterns.

Get in touch with us to discuss which type of grating is best for your application.

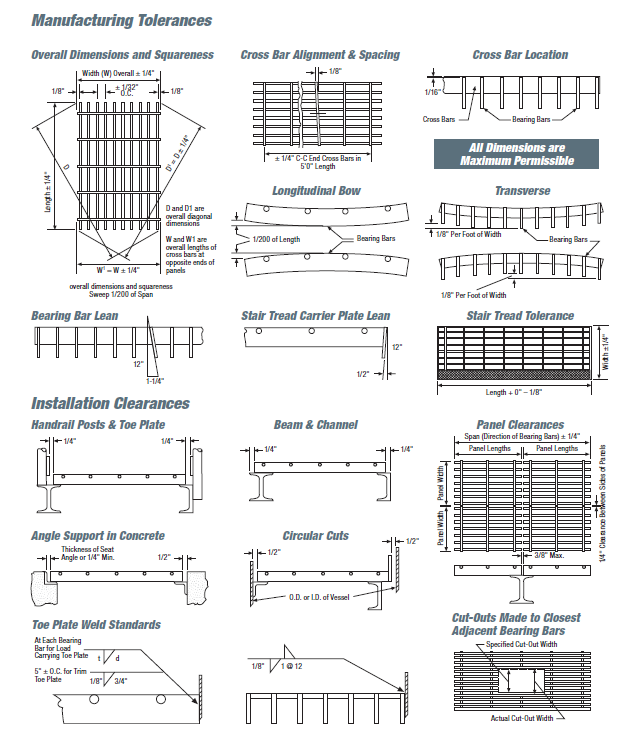

The load tables on the pages within this website provide load/deflection criteria for most common applications. These tables provide a concise reference allowing the specifying authority to select the appropriate bearing bar size and spacing for the intended application. Pedestrian loads are commonly analyzed with uniform and concentrated loads. For pedestrian comfort, deflection is typically limited to 1/4″. Heavy duty and vehicular load tables are presented for specific load conditions. Heavy duty load tables are presented with deflection limited to the lesser of 1/8″ or L/400. If your application is not addressed by the load tables found in this website, please contact Interstate Gratings. We will gladly discuss the merits of our diverse products and assist in selecting the product most appropriate for your application.

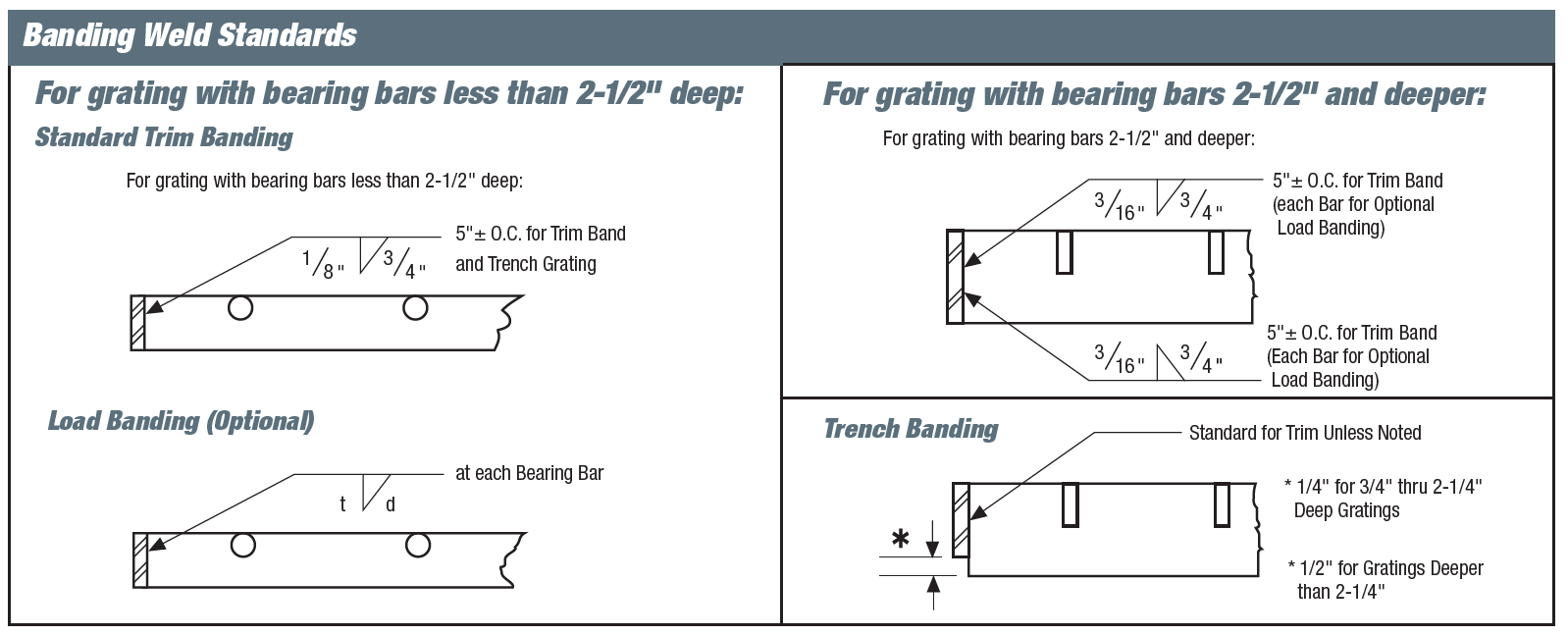

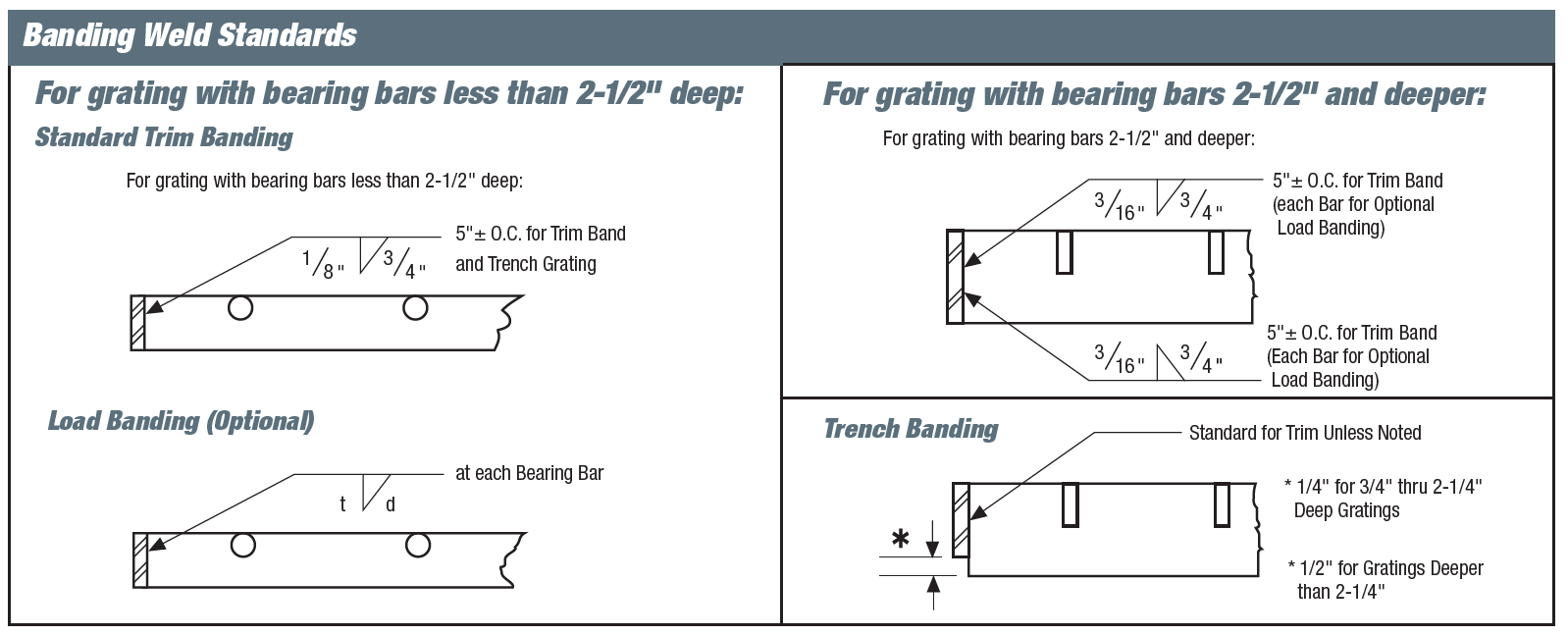

The open ends of the grating panels can be banded to provide additional transverse stiffness and a finished architectural appearance. This is achieved by welding a flat bar, similar in size to the bearing bars, to the cut ends of the grating. Trim banding should always be specified when gratings are designed to be removable. Banding can reduce impact stresses by transferring loads to adjacent bearing bars and should always be specified when the grating is subject to vehicular loads. Further banding descriptions and details can be found under Banding/Layout/Fasteners.

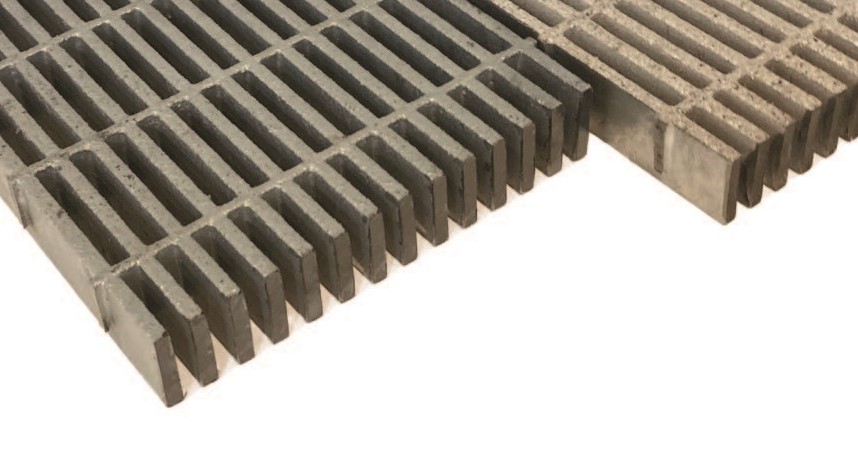

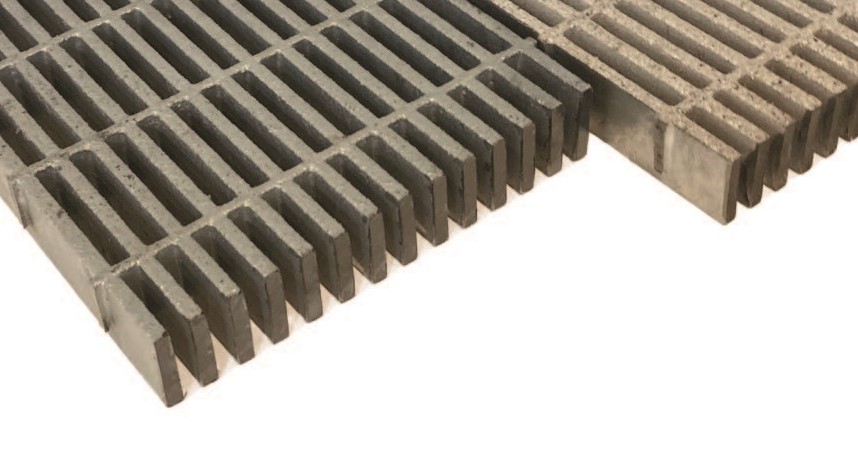

The excellent self-cleaning characteristics of plain surface grating make it suitable for the majority of applications. In the presence of fluids or materials that could cause the top surface of the grating to become wet or slippery, specification of the optional serrated surface should be considered. When serrated grating is specified, the bearing bar depth must be 1/4″ greater than the sizes shown on the load tables to provide the equivalent strength of non-serrated gratings.

IG GRITWELD™ utilizes processes developed for thermal sprayed hard surfacing and incorporates anti-skid ingredients to the super hard substrate. IG GRITWELD™ offers the ultimate in traction and longevity for extreme environments. It is usually applied after galvanizing but can be applied prior to the coating process as well.

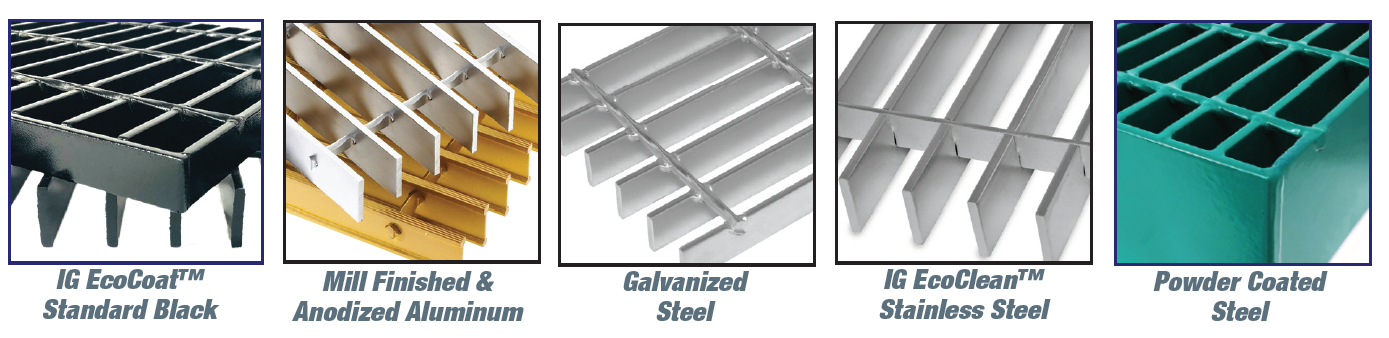

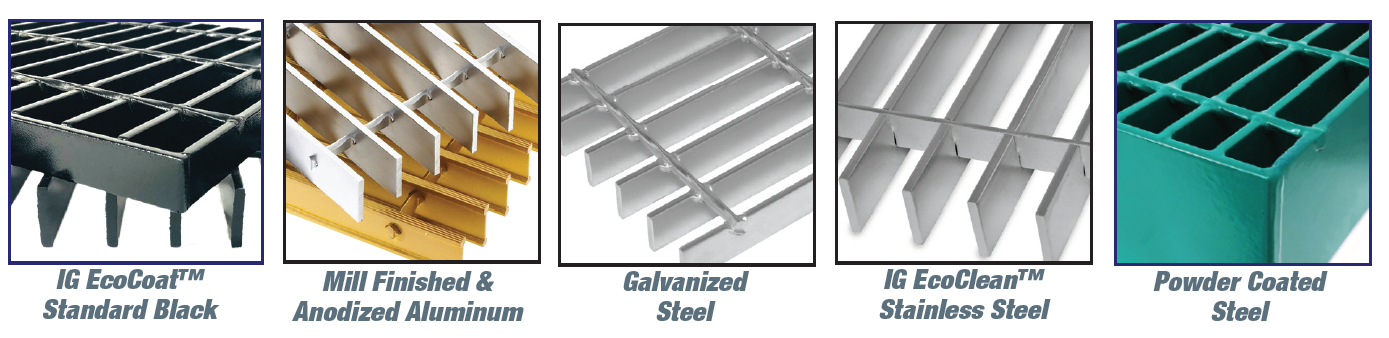

Steel grating is usually provided with bare steel (no finish), painted with one coat of IG ECOCOAT™ or other special paint finishes, or hot dip galvanized in accordance with ASTM A-123. Aluminum products are commonly supplied mill finish but they are also available with optional chemically cleaned or anodized finishes. Due to discoloration that occurs during welding and fabrication, Stainless Steel grating products typically require secondary cleaning.

IG ECOCLEAN™, abrasive blasting, and passivation provide a uniform and clean surface. All grating products can be provided with specialty finishes including enamel, epoxy paints or powder coating. When considering specialty finishes, consultation with the coating manufacturer is essential.

Our team is standing by to help with your grating.

As manufactured, grating panels are provided with open ends. Optional trim banding, a metal flat bar welded to the open ends of the panel, provides additional transverse stiffness and a finished architectural appearance. Banding should be specified for all removable grating panels, the closed end of a banded panel providing additional worker safety during the removal and replacement process.

Gratings subject to vehicular loads should always be specified as banded. In these applications, the band bar helps reduce impact stresses by transferring loads to adjacent bearing bars and further resists deformation caused by repetitive traffic patterns on open end gratings.

Trench banding, where the band bar is elevated above the bottom of the bearing bars, is appropriate for drainage applications. The elevated band bar allows for efficient drainage and will not trap liquids between the band bar and the grating support.

Load banding, where each bearing bar is welded to the band bar, helps distribute load throughout the grating panel. See Banding Weld Standards for specific welding practices.

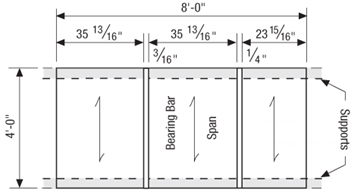

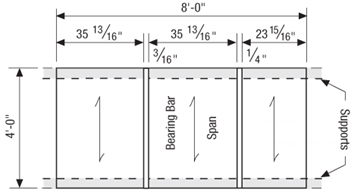

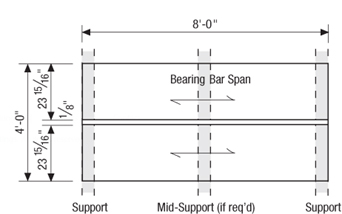

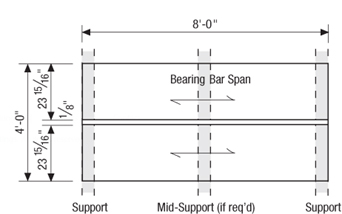

Stock grating panels are manufactured in nominal 24″ and 36″ wide panels. These sizes allow for efficient layout and waste minimization when fabricated to your exact specification. Unlike competing grating products, individual grating panels do not require supports on all four sides of each cut piece.

Bar grating panels only require support perpendicular to the bearing bar span. There is no need to place supports parallel to the bearing bars where adjacent panels are installed in succession. The following diagrams illustrate proper layout and support of a simple bar grating platform.

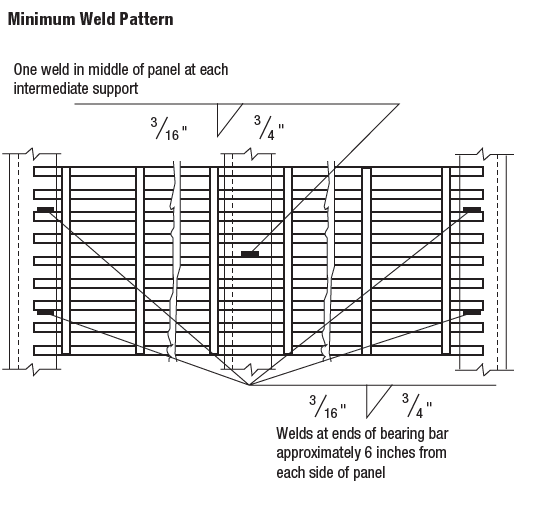

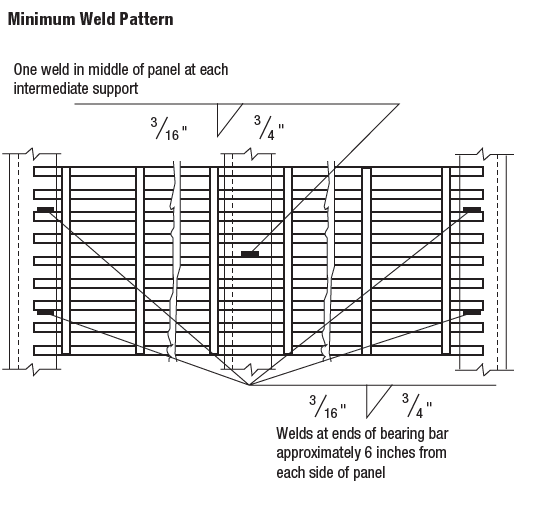

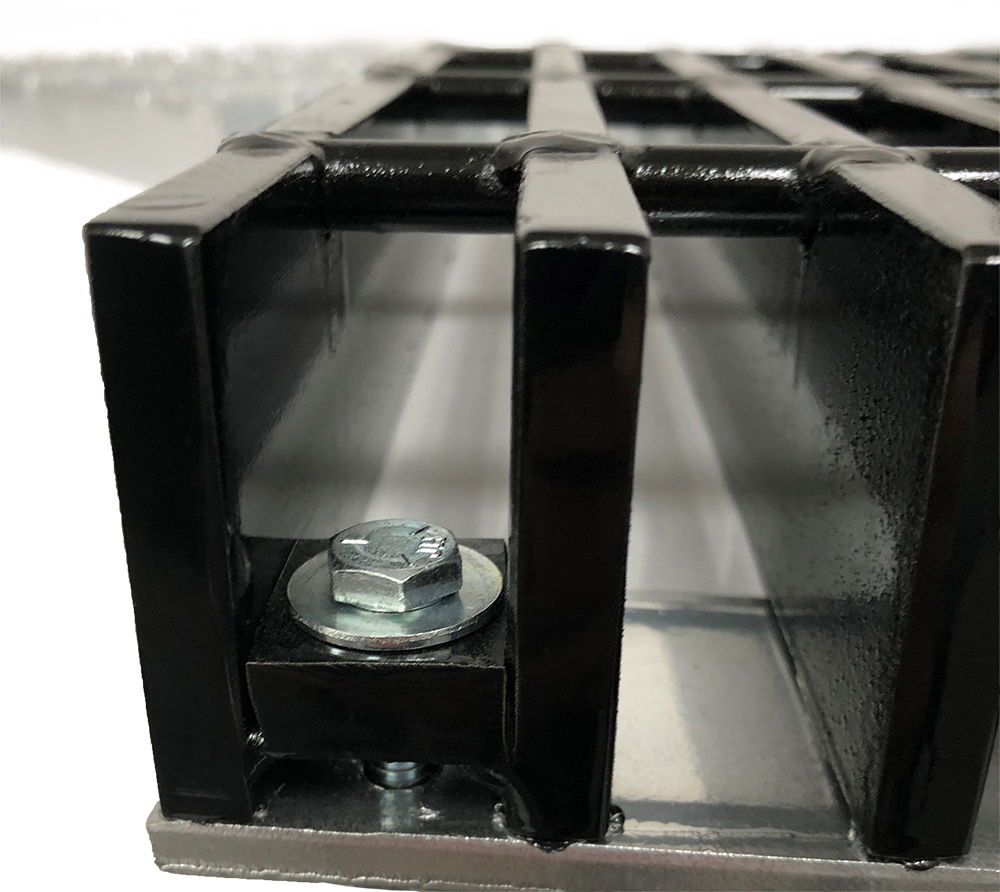

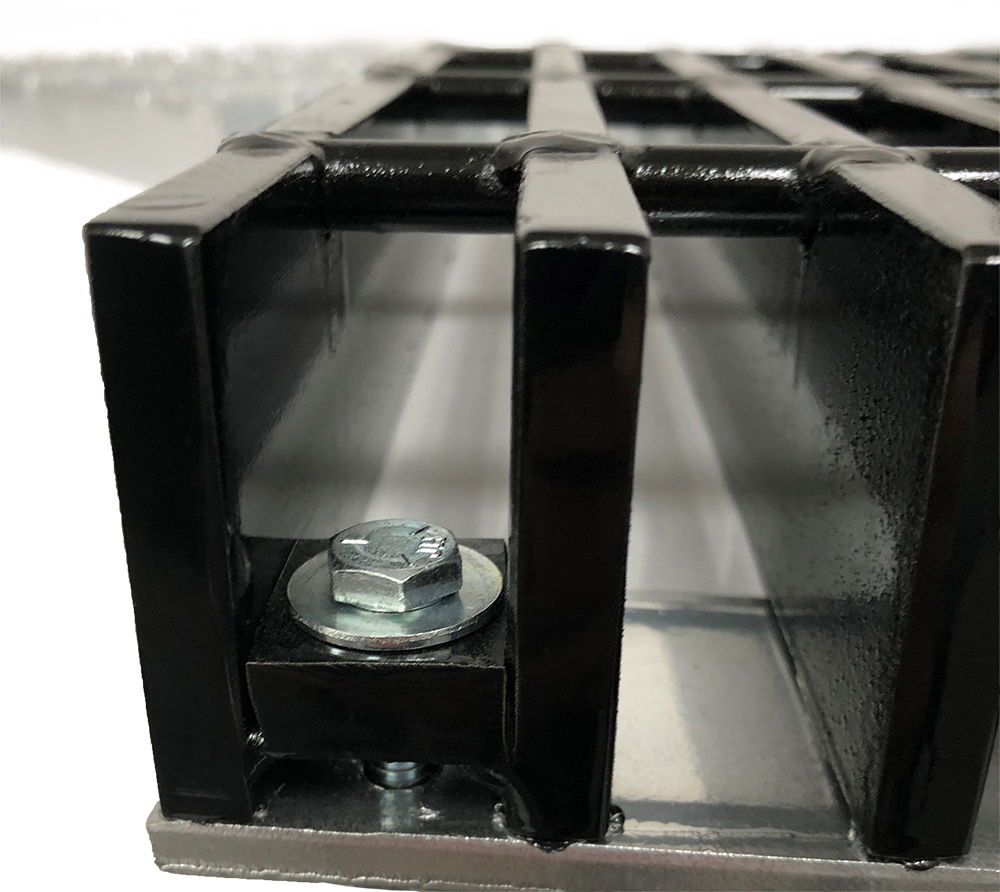

All grating must be firmly fastened in place and welding panels to the supporting structure provides a superior, permanent installation. The diagram below indicates the recommended minimum weld size and spacing for pedestrian applications. This minimum spacing also applies to pedestrian applications where mechanical fasteners are specified. Vehicular applications typically require additional welding, size and spacing as determined by the specifying authority.

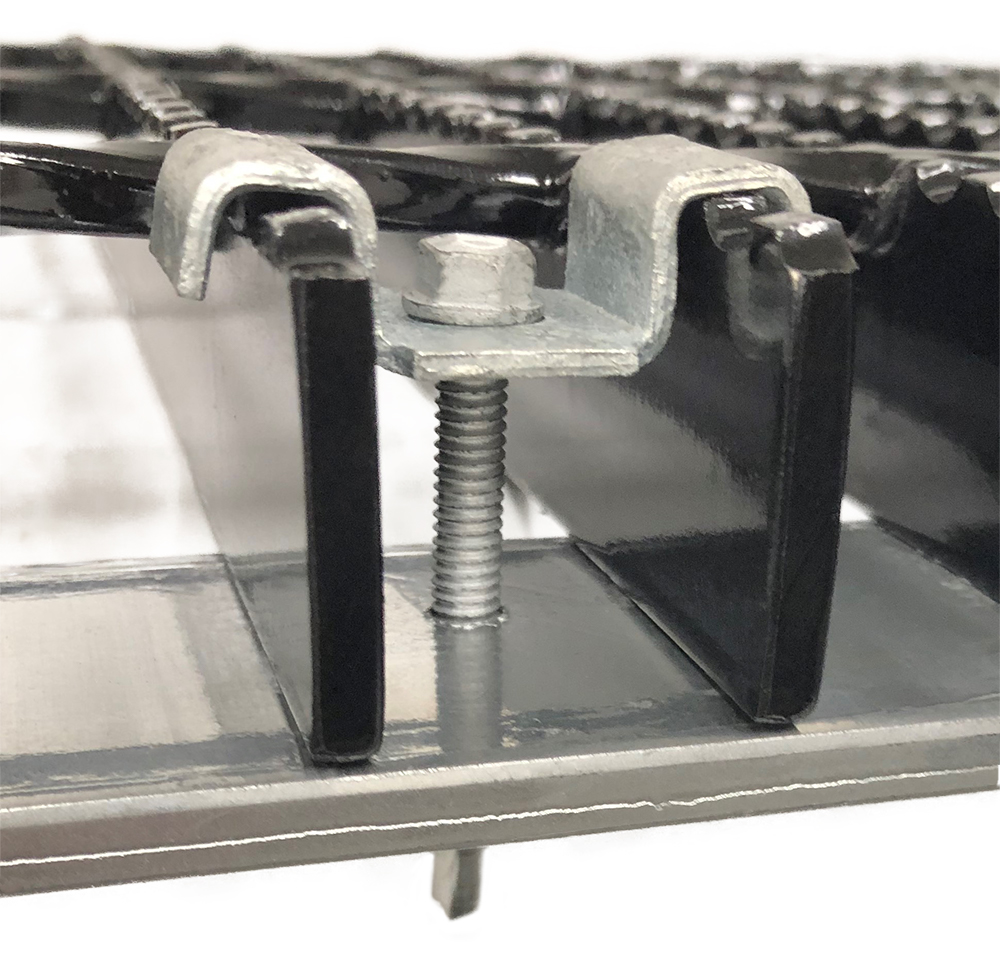

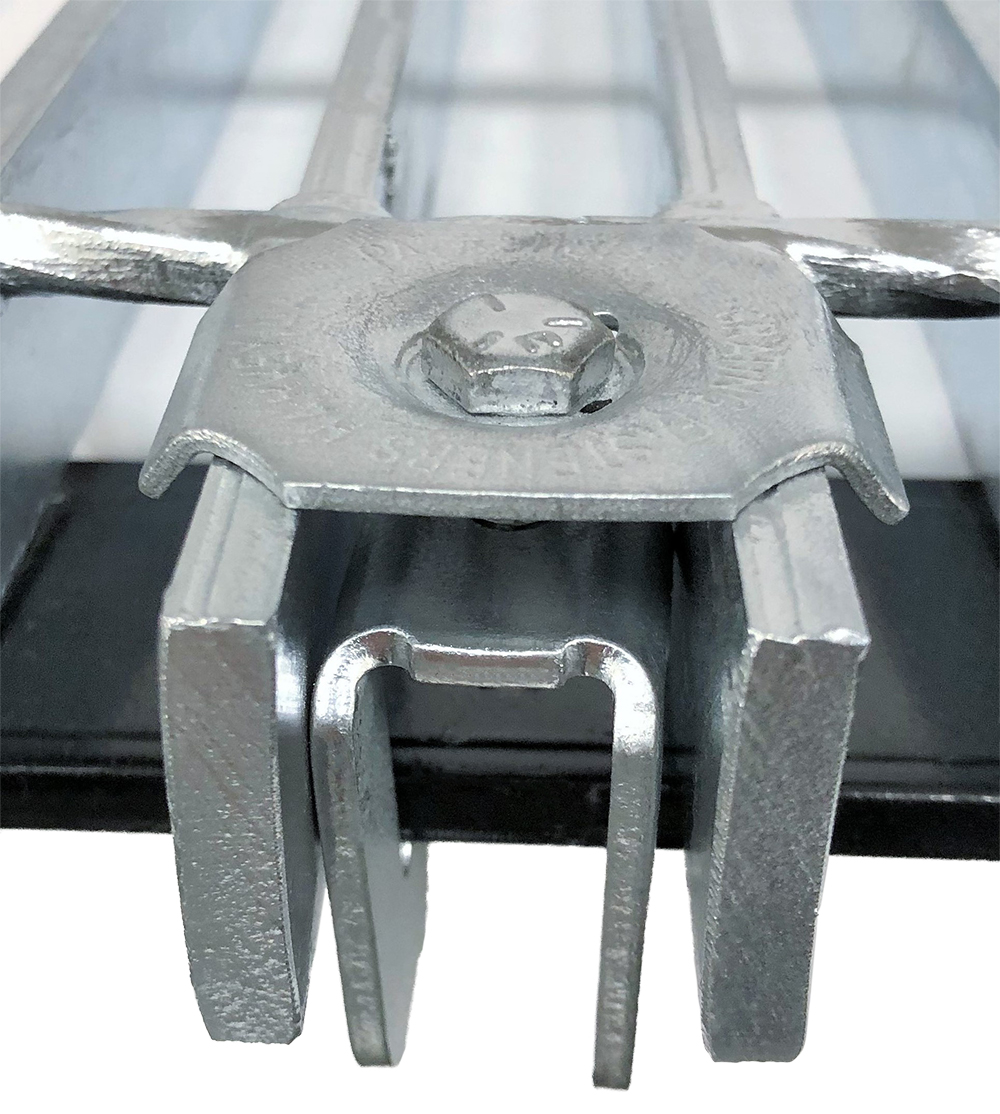

Bent clips bridging two bearing bars, available in galvanized steel, stainless steel or aluminum. Standard bolt holes are 5/16″. Available for 19 & 15 space grating. Not recommended for Heavy Duty applications.

Tek Screws

Clima Seal or Stainless Steel Tek Screws are available to order upon request.

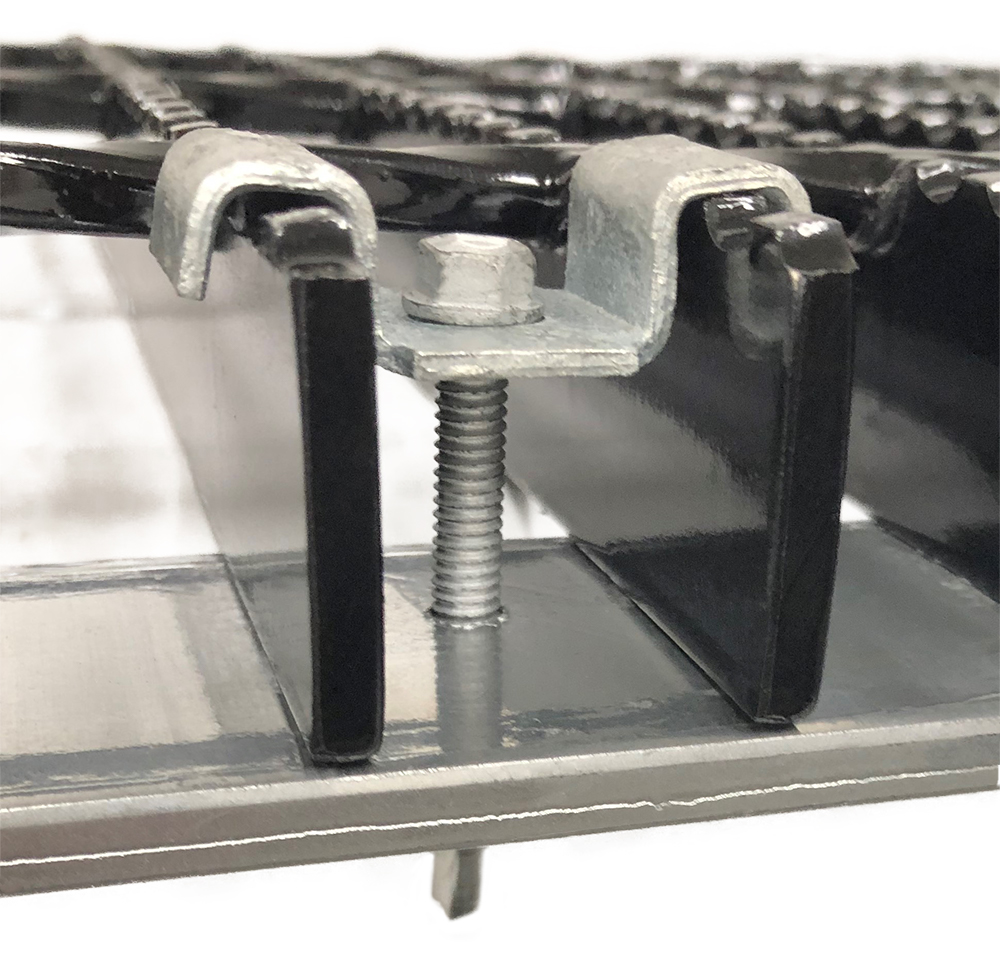

Mechanical fasteners that are installed on the top surface of the grating and create a friction connection with the flange supporting the panel. “G” clips are easily installed without drilling or welding. Available for 19 & 15 space grating. Not recommended for Heavy Duty applications

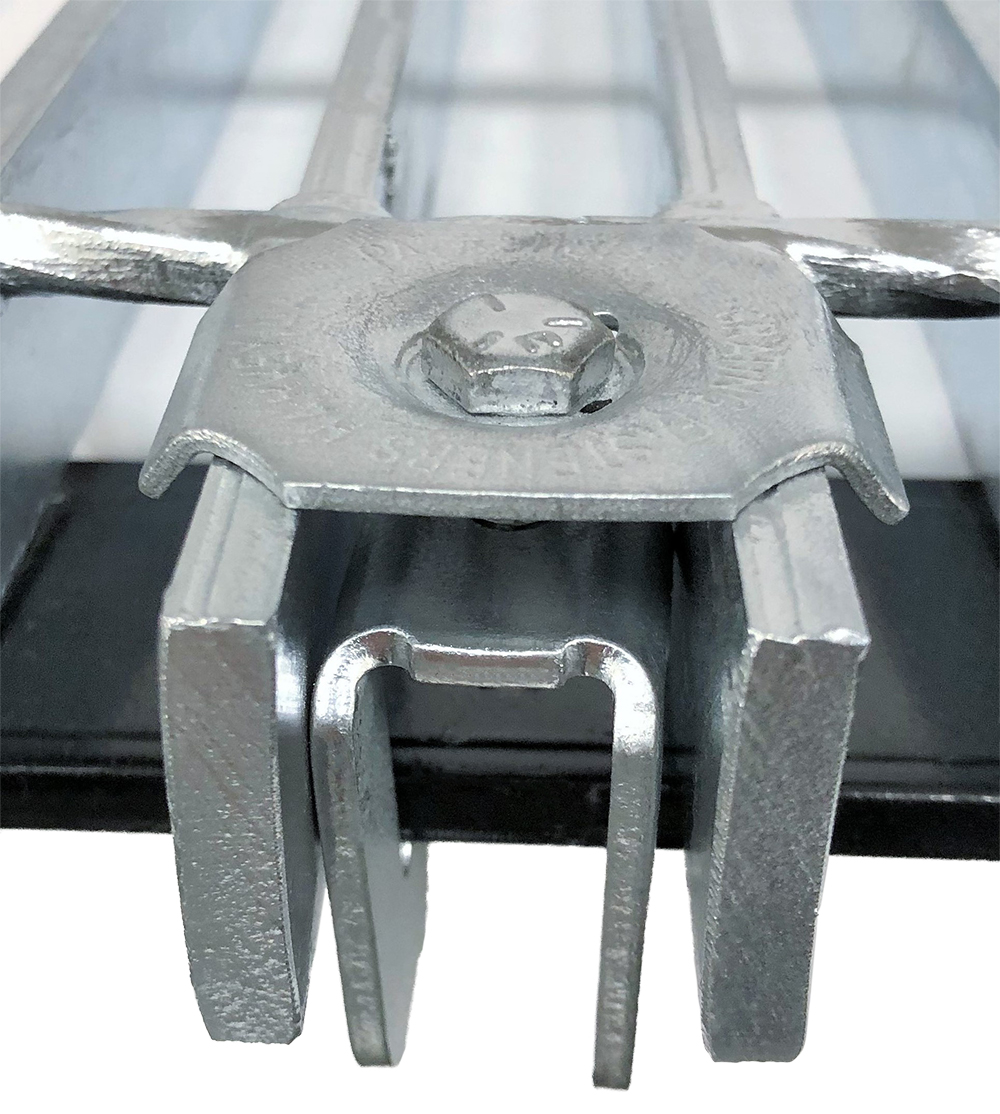

Plates punched with holes and shop welded between the bearing bars to facilitate bolting to the supporting structure. Bolts, screws or other connecting hardware shall be supplied by others.

To be used with narrow spacing of close mesh gratings that require a solid fastener. Counter bore allows for the use of self-drilling fasteners which are recessed below the top surface. Bolts, screws or other connection hardware shall be supplied by others.

Steel Bar Grating is manufactured from ASTM A-1011 mild carbon steel and is available in three distinct products, type “W” Welded Bar Grating, type “DT” Dovetail Pressure Locked Grating, and type “SL” Swage Locked Grating. All three products are available with bearing bar spacing ranging from 19/16″ (1-3/16″) to 7/16″ on center and with cross bars at either 4″ or 2″ on center. Each product is available with the standard plain or optional serrated surface, and each product is available with a bare steel, painted or galvanized finish.

Our most economical steel grating products, type “W” Welded Steel Gratings are manufactured by forge welding rectangular bearing bars and drawn cross bars. This welding process provides a positive fused connection providing years of service under the most demanding conditions. Type 19-W-4 steel grating is our most popular product and is recommended for nearly all industrial flooring applications. With nearly 80% open area, 19-W-4 allows for the easy passage of dirt, debris, snow and liquids and is essentially self-cleaning. Type “W” gratings are available in close mesh ADA conforming spacings 11-W-4 and 7-W-4 which are commonly used in public areas. When specifying type 11-W-4 for ADA applications, 3/16” thick bearing bars must be specified. Click Here* for detailed product specification information.

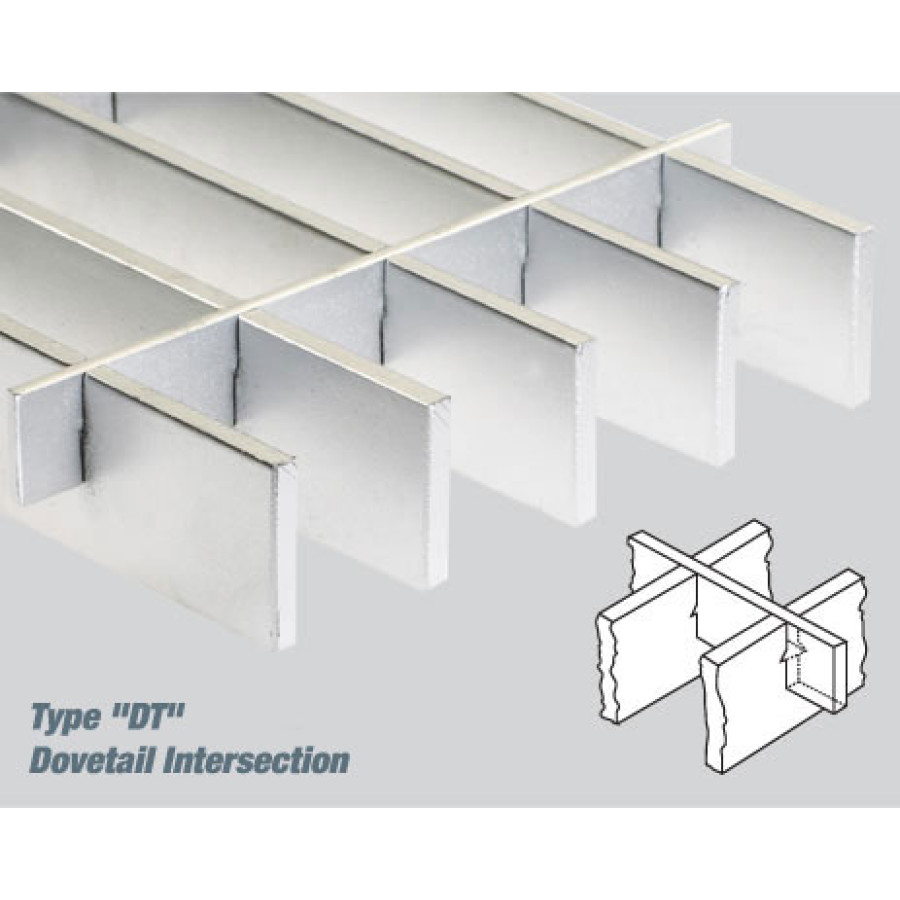

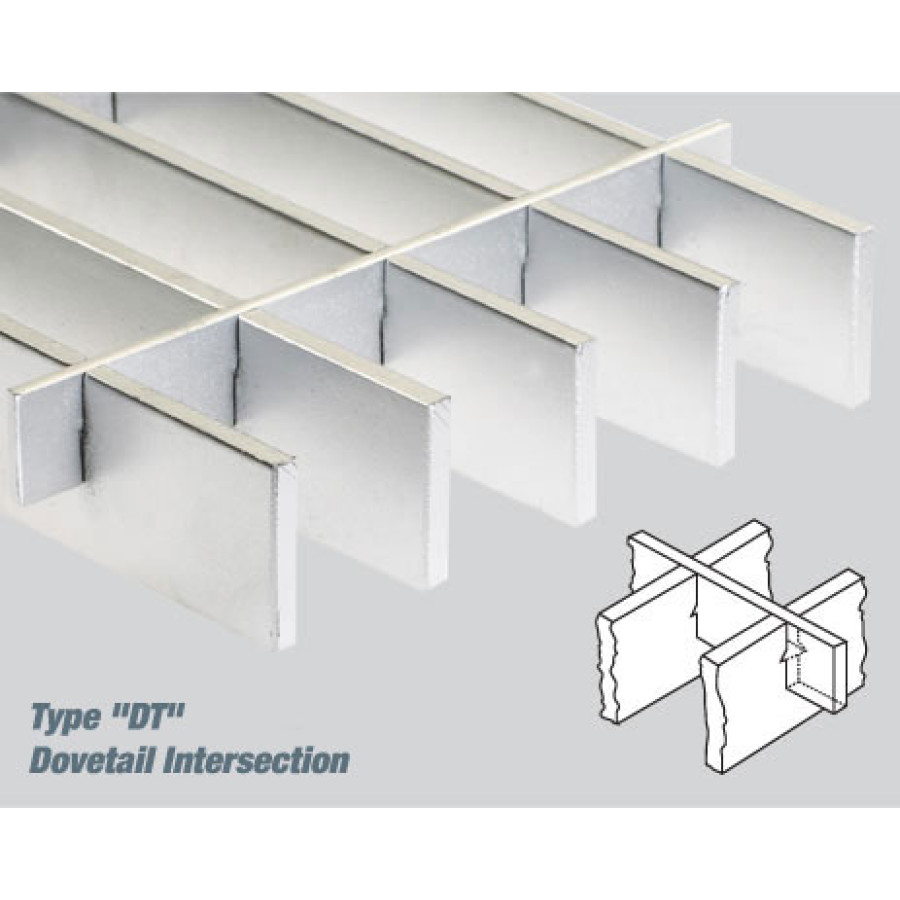

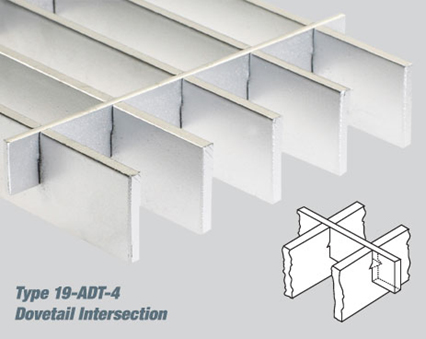

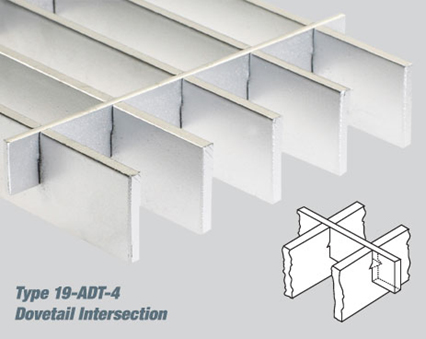

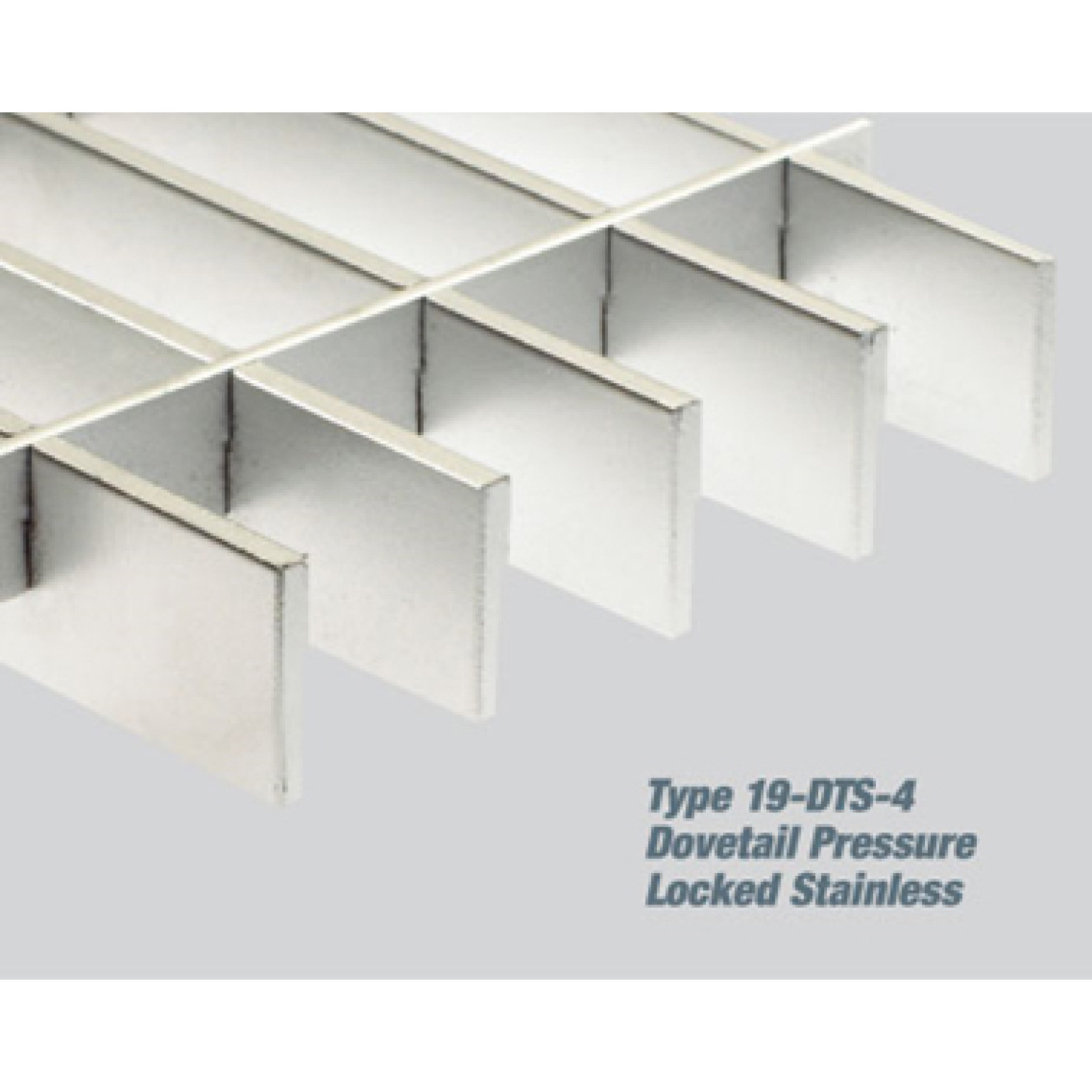

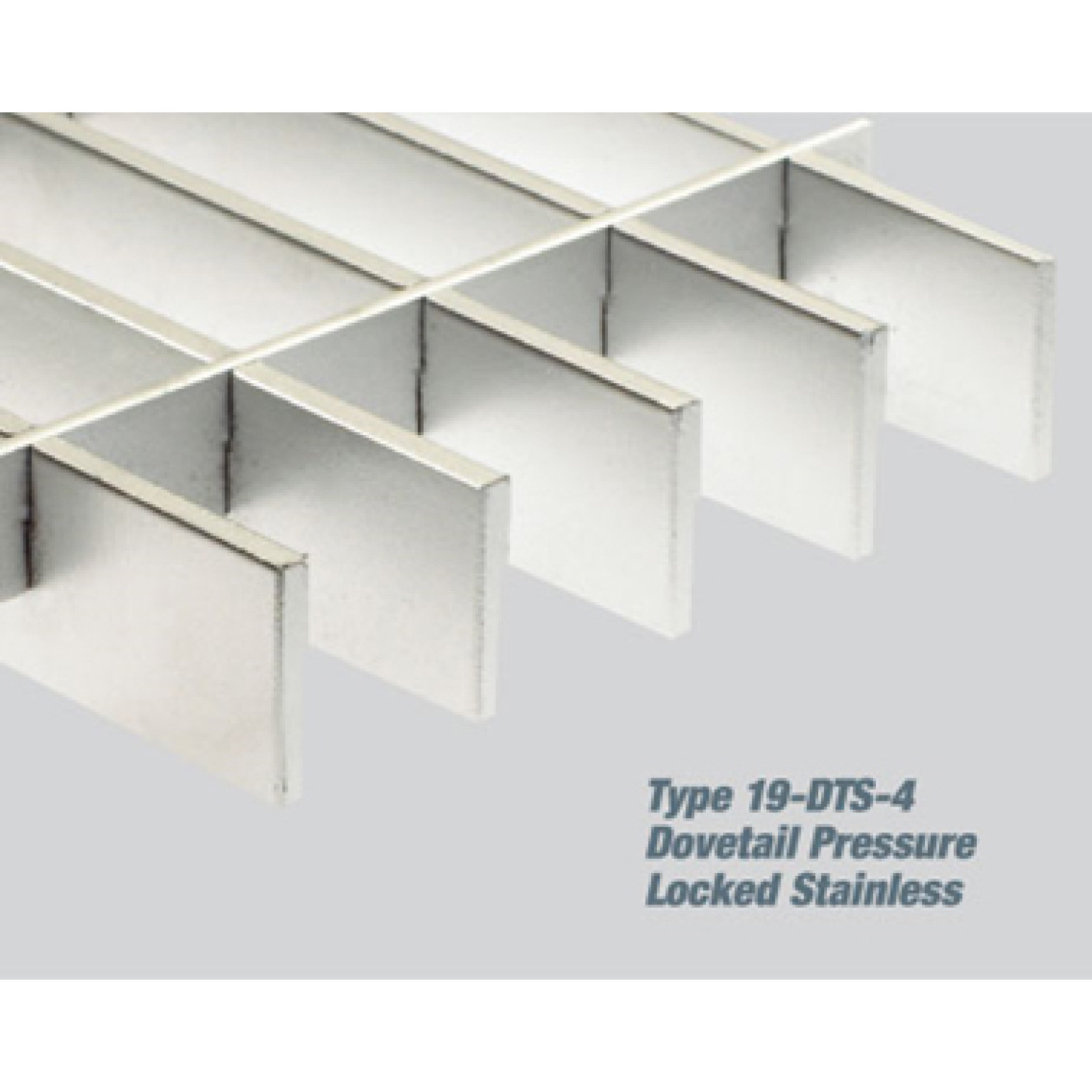

Type “DT” steel gratings have deep rectangular cross bars and are manufactured by inserting pre-punched bearing bars and cross bars into an interlocking configuration and deforming the cross bars under intense hydraulic pressure. The deep cross bars on type “DT” gratings make them popular for architectural applications such as sun shades and infill panels with the deeper cross bar serving as a distinct architectural accent. Click Here* for detailed product specification information.

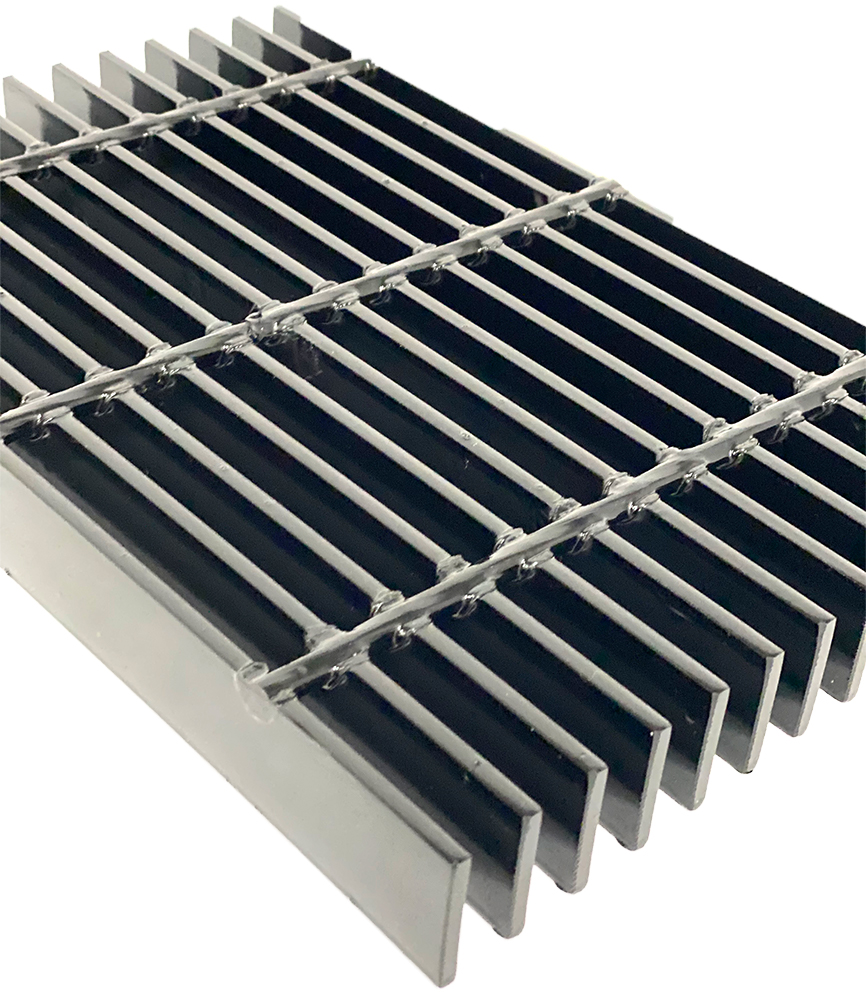

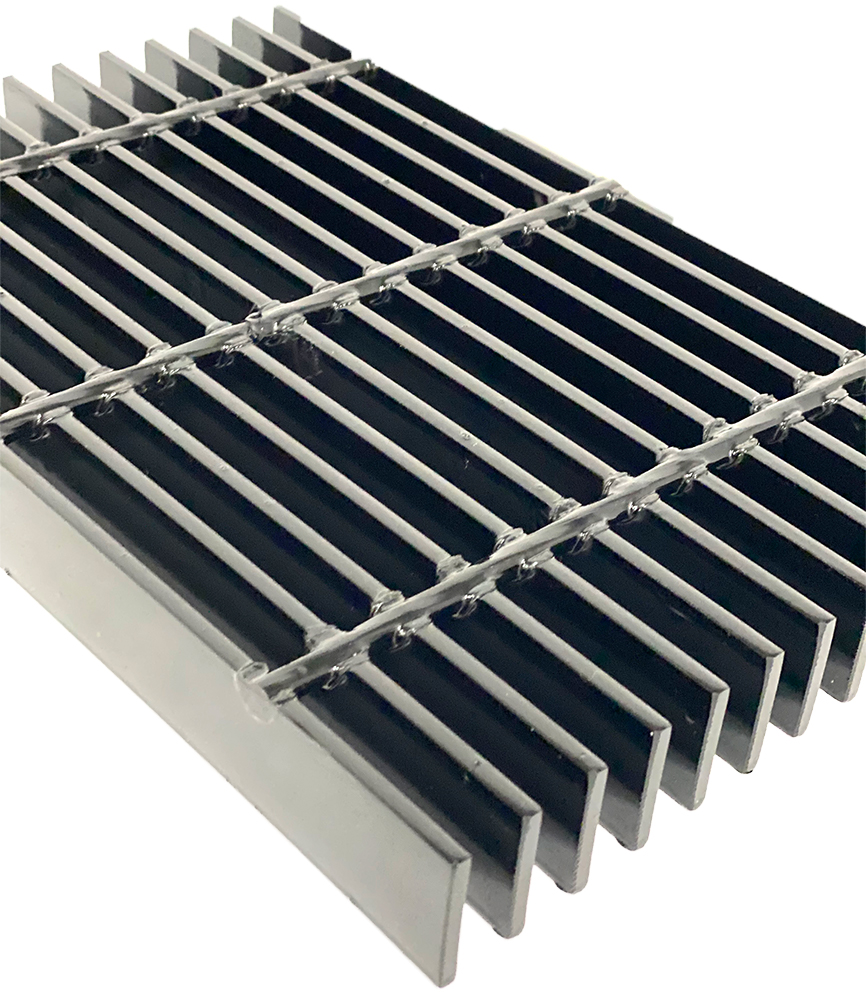

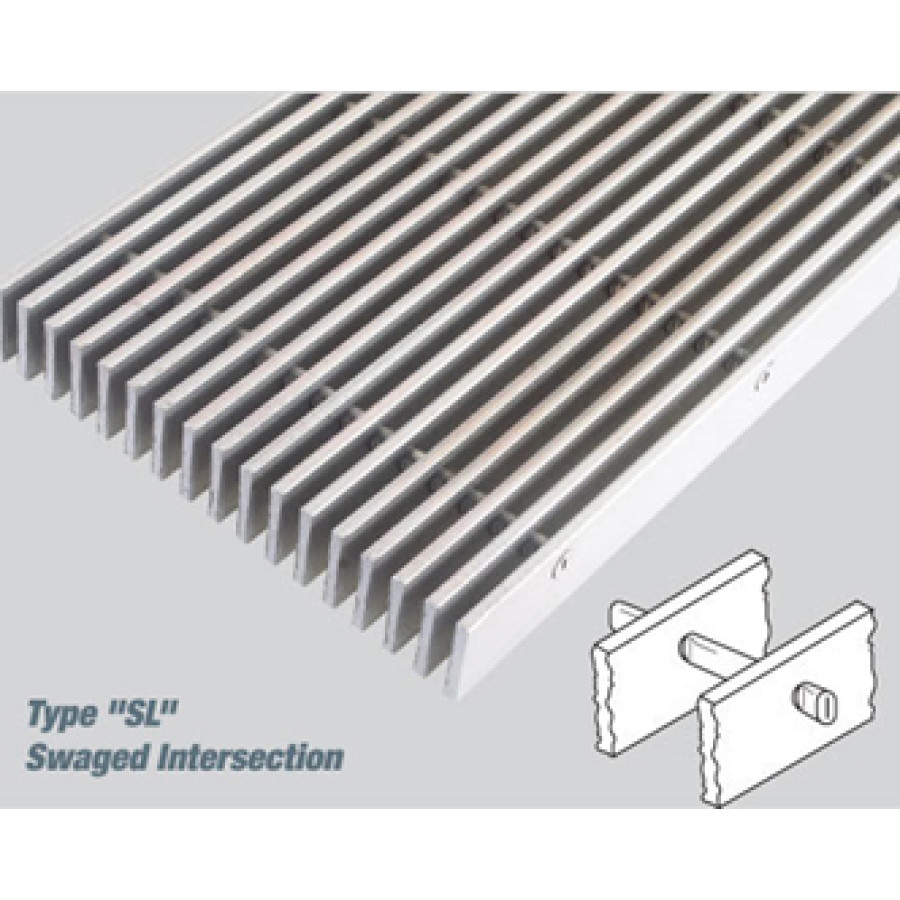

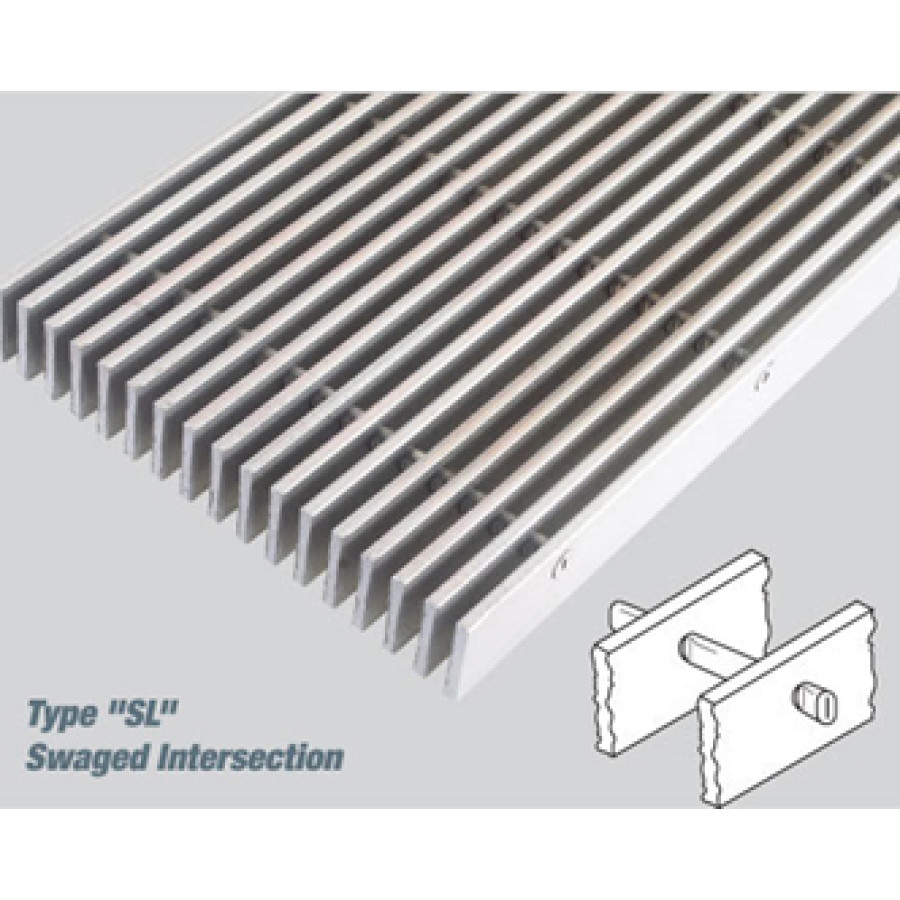

Type “SL” steel gratings are manufactured by inserting hollow tube cross bars into pre-punched holes in the bearing bars and swaging the cross bars forming a positive mechanical connection. The cross bars are recessed below the top surface of the bearing bars providing a uniform and attractive architectural appearance. Swage locking is a particularly efficient process for the production of close mesh gratings. Type 7-SL-4 with 3/16″ thick bearing bars provides a net 1/4″ clear opening between the bearing bars. This narrow opening is often preferred in public areas where concerns of drainage and the presence of high heeled shoes converge.

Aluminum Bar Grating is lightweight, corrosion resistant, non-sparking and has an unmatched strength-to-weight ratio. Manufactured from ASTM B221, 6063 or 6061 alloy, aluminum grating is available in four distinct products, type “ADT” Dovetail Pressure Locked , type “SG” Swaged Rectangular Bar, type “SGI” Swaged “I” Bar, and type “SGF” Swaged Flush-Top and. All four products are available with bearing bar spacing ranging from 19/16″ (1-3/16″) to 7/16″ on center and with cross bars at either 4″ or 2″ on center. Rectangular bar products are manufactured with standard plain or optional serrated walking surfaces and “I” bar products are manufactured with a standard skid-resistant striated walking surface. Aluminum products are typically shipped “mill finish” with no additional treatment. For architectural applications or highly corrosive environments, supplemental anodizing, chemical cleaning or powder coat finishes are available.

Type “ADT” aluminum gratings have deep rectangular cross bars and are manufactured by inserting pre-punched bearing bars and cross bars into an interlocking configuration and deforming the cross bars under intense hydraulic pressure. The deep cross bars on type “ADT” gratings make them popular for architectural applications such as sun shades and infill panels with the deeper cross bar serving as a distinct architectural accent. Click Here* for detailed product specification information.

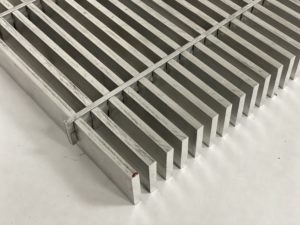

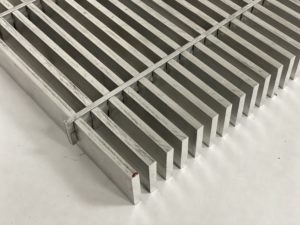

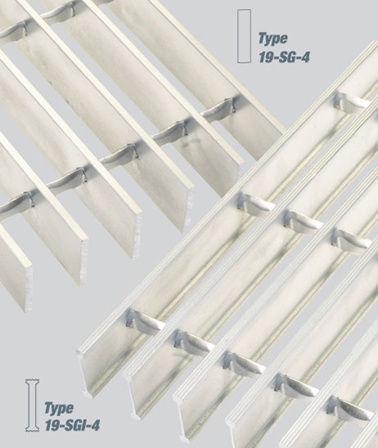

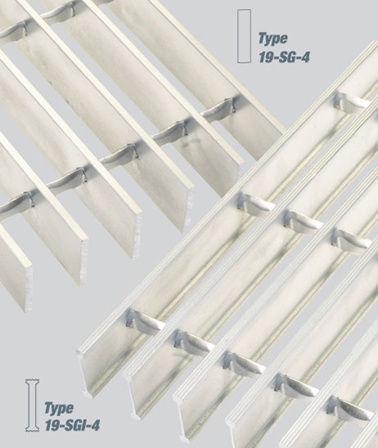

Type “SG” rectangular bar provides clean, crisp lines and the cross bar is fully locked within the bearing bar, slightly below the top surface. Type 19-SG-4 aluminum grating is the industry recognized standard for industrial applications with nearly 80% open area. Type “SG” gratings are available in close mesh ADA conforming spacings 11-SG-4 and 7-SG-4 which are commonly used in public areas. When specifying type 11-SG-4 for ADA applications, 3/16″ thick bearing bars must be specified.

Manufactured with highly efficient “I” shaped extruded bearing bars, type “SGI” aluminum grating carries the same load as 3/16” thick rectangular bar type “SG” aluminum grating, but weighs slightly less per square foot. Additionally, the striated top and bottom flanges of the “I” bar provide enhanced skid resistance without the cost of serration.

Manufactured with a unique, extruded cross bar that is flush with the top surface of the bearing bars after swaging, type “SGF” aluminum grating provides an enhanced walking surface for areas subject to continuous pedestrian traffic. Available in rectangular bar with plain or serrated surfaces, type “SGF” aluminum grating is also available in ADA conforming spacings for applications located in the public way.

Stainless Steel Bar Grating is manufactured from alloy types 304, 304L, 316 and 316L and available in grating types “WS” (welded stainless grating), “DTS” (dovetail stainless pressure locked) and “SLS” (swage locked stainless). Popular for highly corrosive environments and long-lasting architectural applications, stainless steel bar gratings are available with bearing bar spacing ranging from 19/16″ (1-3/16″) to 7/16″ on center and with cross bars at 4″ or 2″ on center. Each product is available with standard plain or optional serrated surface and finish options are diverse and should be closely considered.

Our strongest and most economical stainless product, type “WS” gratings are manufactured by forge welding rectangular bearing bars and drawn cross bars. This welding process provides a positive fused intersection providing years of service under the most demanding conditions.

Type “WS” stainless gratings are available in “19 space” (1-3/16″), “15 space” (15/16″) and “11 space” (11/16″) bearing bar centers. Standard cross bar spacing is 4″ on center and the optional 2″ cross bar spacing is also available.

Click Here* for detailed product specification information.

Manufactured with a deep rectangular cross bar, type “DTS” dovetail stainless grating is commonly preferred for architectural applications. Sunscreens, grilles and infill panels are just some of the applications where this distinct configuration is the ideal building accent.

Type “DTS” stainless gratings are available with bearing bar spacings ranging from 19/16″ (1-3/16″) to 7/16″ on center. Click Here* for detailed product specification information.

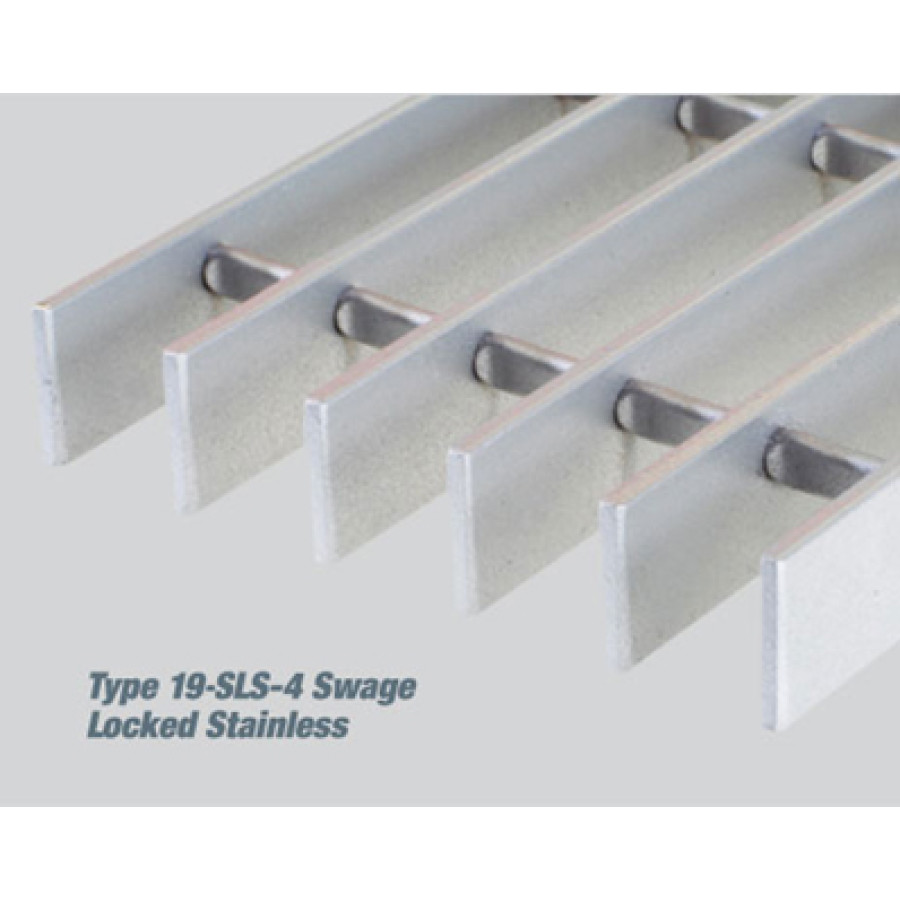

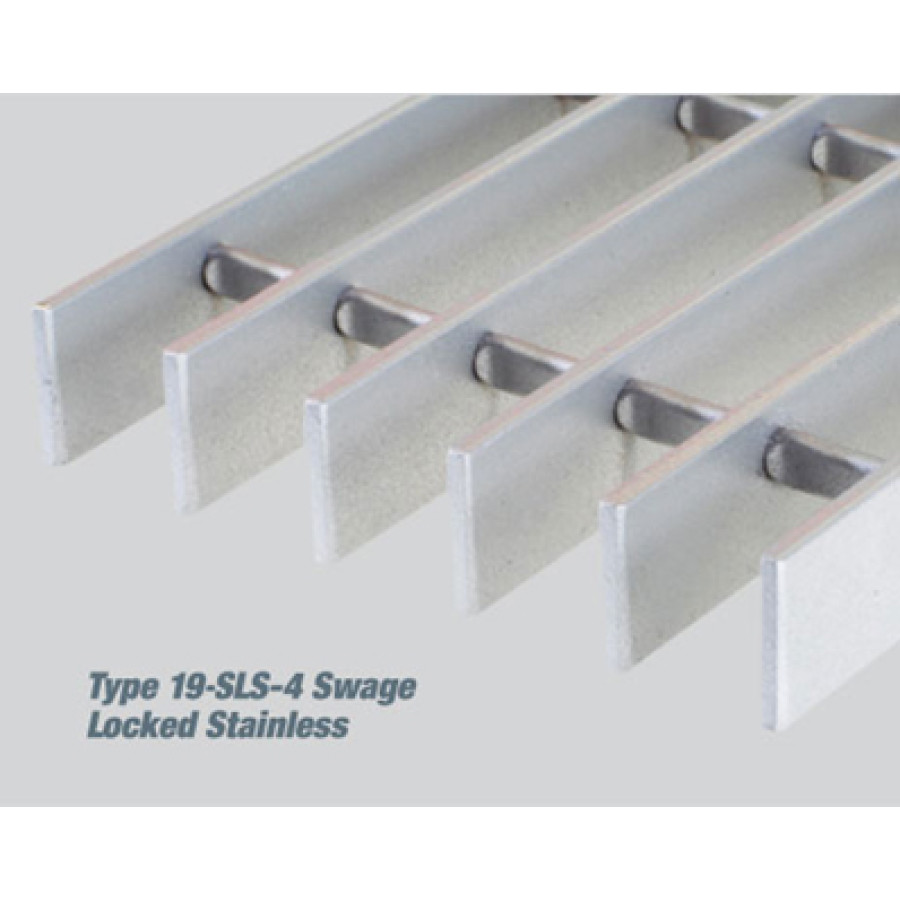

Hollow tube cross bars are hydraulically swaged into pre-punched holes in the bearing bars to make type “SLS” swage locked stainless grating. This type of construction provides a secure bearing bar/cross bar intersection and products are available with bearing bar spacings ranging from 19/16″ (1-3/16″) to 7/16″ on center.

This attractive grating, with the swaged cross bars slightly below the top surface of the grating, is very popular for “close-mesh”, ADA conforming applications. Consider “11 space” or “7 space” gratings for vault covers or entrance mats located in the public way.

As produced, stainless steel products typically display discoloration caused by the introduction of heat during welding, cutting or grinding processes. If appearance is important to your application, consideration should be given to secondary cleaning or electro-polishing.

Products will display discoloration from welding, cutting and grinding. Satisfactory for industrial or process applications where appearance is not a consideration.

A uniform, matte finish is achieved by abrasive blasting followed by passivation to remove manufacturing contaminants.

Anchor

– A device by which grating is attached to its supports

Band

– A flat bar welded to the end of a grating panel, or along the side of a cutout, and extending neither above nor below the bearing bars.

Load Carrying Band

– A band used to transfer load between bearing bars.

Trim Band

– A band which carries no load, used primarily for appearance and closing open ends.

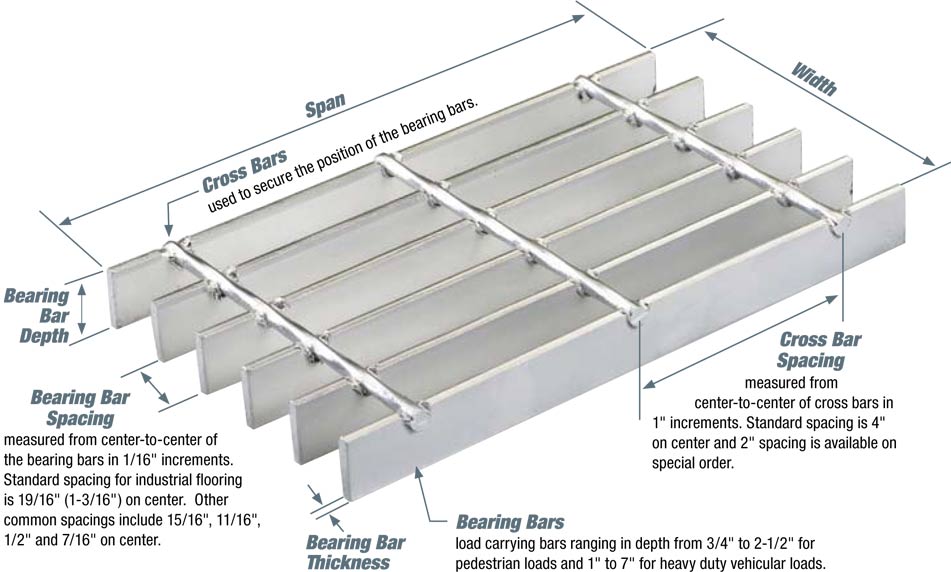

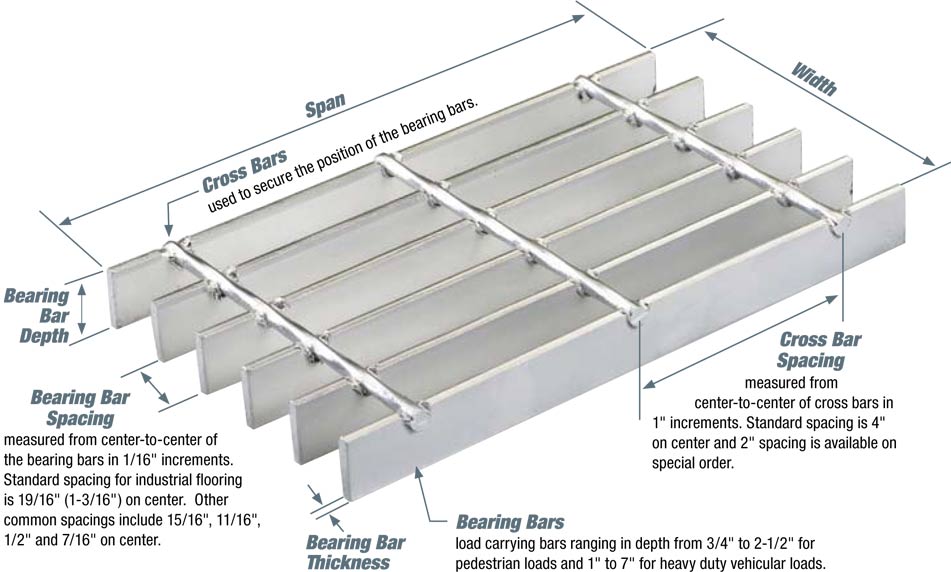

Bearing Bars

– Load-carrying main elements made from steel, aluminum or stainless steel, extending in the direction of the grating span

Bearing Bar Centers

– The distance center-to-center of the bearing bars.

Carriers

– Flats or angles which are welded to the grating panel and nosing of a stair tread and are bolted to a stair stringer to support the tread.

Clear Opening

– The distance between faces of bearing bars in rectangular gratings, or between a bent connecting bar and a bearing bar in a riveted grating.

Cross Bars

– The connecting bars which extend across the bearing bars, usually perpendicular to them. The may be bent into a corrugated or sinuous pattern and, where they intersect the bearing bars, are welded, forged or mechanically locked to them.

Pressure-Locked Grating

-Pressure-locked means bearing bars are locked in position by cross bar deformation instead of riveting or welding. Several proven methods include:

• Expansion of an extruded or drawn tubular cross bar;

• Extruded cross bar deformed or swaged between bearing bars;

• Press assembly of rectangular cross bars into slotted bearing bars.

Radially Cut Grating

– Rectangular grating which is cut into panels shaped as annular segments, for use in circular or annular areas.

Reticuline Bar

– A sinuously bent connecting bar extending between two adjacent bearing bars, alternately contacting and being riveted to each.

Rivet Centers

– The distance center-to-center of rivets along one bearing bar.

Riveted Grating

– Grating composed of straight bearing bars and bent connecting bars, which are joined at their contact points, by riveting.

Serrated Grating

– Grating which has the top surfaces of the bearing bars or cross bars, or both, notched.

Cross Bar Centers

– The distance center-to-center of the cross bars.

Curved Cut

– A cutout following a curved pattern.

Cutout

– An area of grating removed to clear an obstruction or to permit pipes, ducts, columns, etc. to pass through the grating.

Electro-Forged

– A process of combining hydraulic pressure and heat fusion to forge bearing bars and cross bars into a panel grid.

Finish

– The coating, usually paint or galvanizing, which is applied to the grating.

Flush-Top Grating

– A type of pressure-locked grating in which the cross bars and bearing bars are in the same plane relative to the top surface of the grating.

Grating

– An open grid assembly of metal bars, in which the bearing bars, running in one direction, are spaced by rigid attachment to cross bars running perpendicular to them or by bent connecting bars extending between them.

Hinged Panel

– Grating panels which are hinged to their supports or to other grating parts.

I-Bar

– An extruded aluminum bearing bar having a cross section shape of the letter “I”.

Length

– Refer to Span of Grating

Nosing

– A special “L” section member serving as the front or leading edge of a stair tread, or of grating at the head of a stair.

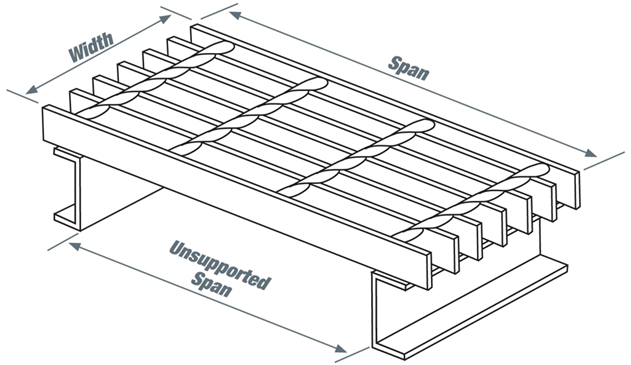

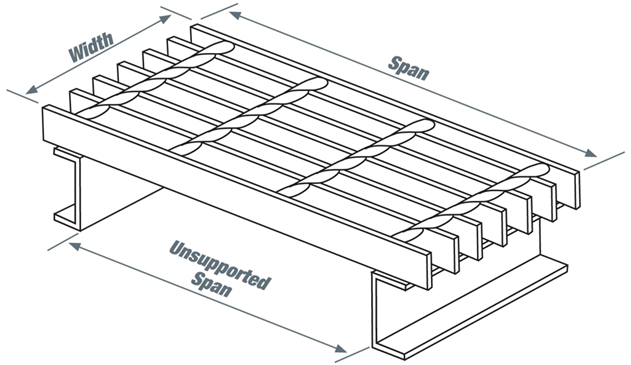

Span of Grating

– The distance between points of grating support, or the dimension of the bearing bars in this direction.

Straight Cut

– That portion of the cut edge or cutout of a grating which follows a straight line.

Swaging

– A method of altering the cross-section shape of a metal bar by pressure applied through dies.

Toe Plate

– A flat bar attached against the outer edge of a grating or rear edge of a tread, and projecting above the top surface of the grating or tread to form a lip or curb.

Tread

– A panel of grating having carriers and a nosing attached by welding, and designed specifically to serve as a stair tread.

Welded Grating

– Grating in which the bearing bars and cross bars are joined at their intersections by either electro-forging or conventional hand welding.

Width

– The overall dimension of a grating panel, measured perpendicular to the bearing bars, and in the same direction as the cross bars.

Interstate Gratings, LLC

1820 West 200 South

Lindon, UT 84042